Our Services

Explore our diverse range of services tailored to meet your cutting and material processing needs. From advanced 5-axis waterjet cutting to precise plasma table cutting, along with expert design, drafting, welding, and fabrication services, we ensure top-notch quality and dynamic in every project.

Call Us: +1 (403) 342-0866

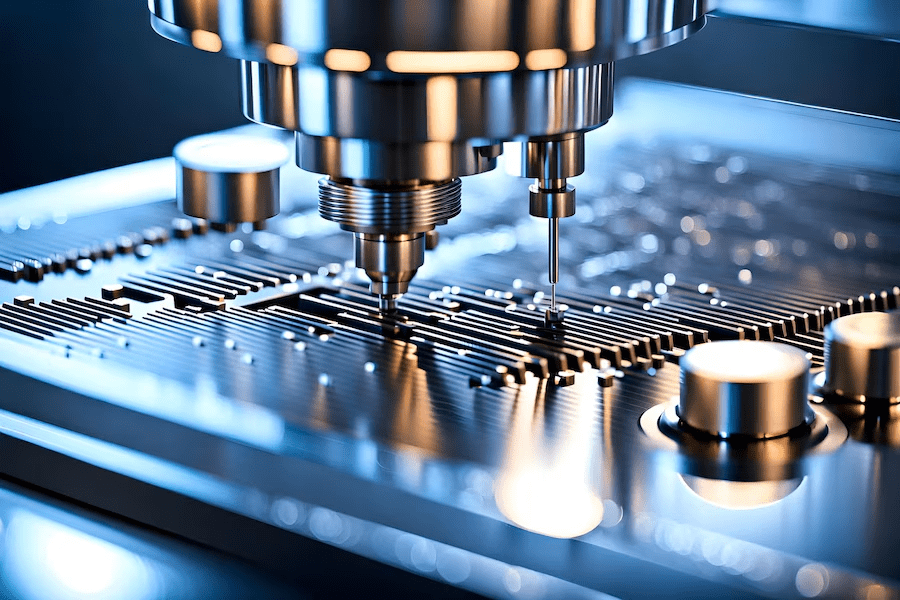

5 Axis Waterjet Cutting

Experience dynamic like never before with our cutting-edge 5-axis waterjet cutting technology. From the best designs to complex bevelled edges, we deliver exceptional results tailored to your needs. With unparalleled accuracy and versatility, we ensure your projects are executed with the highest level of quality and dynamic.

Plasma Table Cutting

Effortlessly cut through thick materials and high-end designs with our high-powered plasma table-cutting services. We offer rapid production and precise shapes, ensuring your projects are executed with efficiency and accuracy. Trust our advanced technology and skilled craftsmen to deliver superior results for all your plasma-cutting needs.

Design and Drafting

From concept to completion, our design and drafting services bring your visions to life. Our expert team meticulously translates your ideas into detailed plans and blueprints, ensuring dynamic and accuracy every step of the way. With innovative solutions tailored to your specifications, we transform concepts into reality, setting the foundation for successful projects.

Welding & Fabrication

Count on our expert craftsmen for top-notch welding and fabrication services. From advanced metalwork to structural projects, we deliver dynamic and durability with every weld. Our meticulous attention to detail ensures the highest quality in every fabrication job, guaranteeing your projects are completed to perfection. Trust us to bring your ideas to life with skill and expertise.

Get a Quote Now

Ready to get started? Contact us today for a quote tailored to your specific needs. Let’s bring your cutting and material processing projects to life together. Get in touch now!

"*" indicates required fields

Related Services

We offer a variety of services, including design, drafting, waterjet cutting, plasma cutting, and welding. We have also partnered with various other companies for powder coating and forming.

A 5-axis cutting head can be used to cut 4-axis parts, where the bottom surface geometries are shifted a certain amount to produce the appropriate angle, and the Z-axis remains at one height. This can be useful for applications like weld preparation, where a bevel angle must be cut on all sides of a part that will later be welded. Of course, a 5-axis head can cut parts where the Z-axis is also moving along with all the other axes. This full 5-axis cutting could be used for cutting contours on various surfaces of formed parts.

- Waterjets can machine any material that lasers cannot, particularly reflective materials such as aluminum and copper.

- The material being cut by a waterjet does not experience thermal distortion or edge hardening, whereas lasers create burned, hardened edges.

- Dynamic water jets can obtain the same tolerances as lasers on thin parts and higher tolerances on parts thicker than 0.5″.

- Waterjets do not lose much focus when cutting over uneven surfaces; lasers do.

- Waterjets create much cleaner edge quality.

- Fast turn-around.

- Waterjets are much faster than EDM.

- Waterjets cut a wider variety of materials.

- Uniformity of material is not very important to a water jet.

- Waterjets make their own pierce holes.

- Waterjets do not heat the surface of the material.

- Waterjets are useful for creating start holes for EDM wire insertion.

- Waterjets require less setup.

- Larger parts can be cut on a water jet.

- Fast turn-around.

- There is only one tool on a water jet.

- Cleanup is much faster with a water jet.

- Programming is faster and easier.

- Mills cannot cut hard or brittle materials such as Titanium or Inconel.

- Fast turn-around.

- Lower cost per piece for short runs.

- Cut holes closer to the edge of the material with a water jet.

- Minimal setup.

- Punch press cannot cut thick, brittle, or hard materials.

- Fast turn-around.